Where did the idea come from for Aceleron?

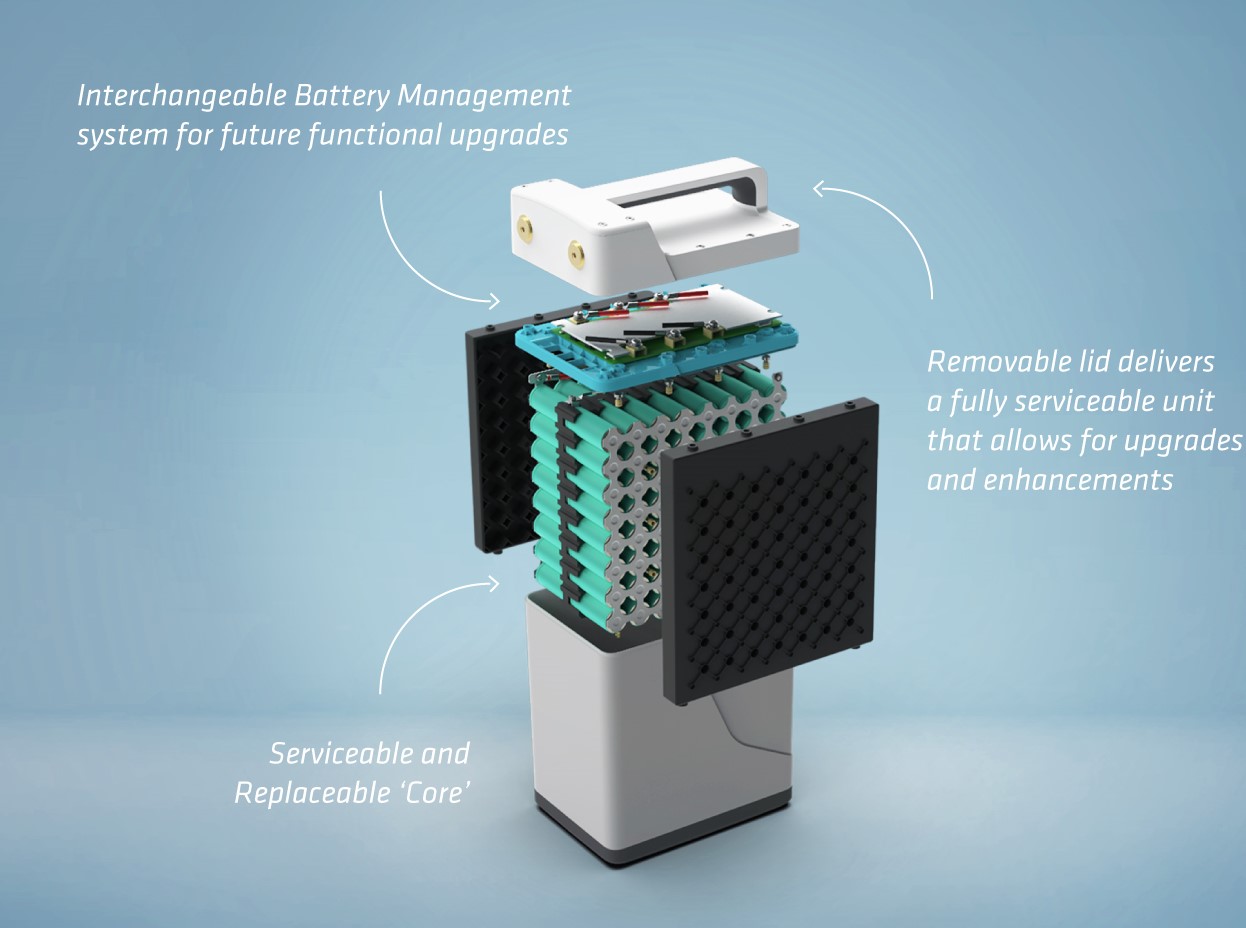

With backgrounds in engineering, Aceleron started as a lunchtime conversation between co-founders Dr Amrit Chandan and Carlton Cummins who realised that conventional battery packs are not designed to be easily taken apart for repair, reuse and recycling. Through the process of disassembling many lithium battery packs they came up with a new way of designing batteries which enables easy maintenance and repair.

Why is the work you’re doing so important?

We believe that it’s our duty and responsibility to design products that positively impact the lives of their users and meet the needs of both our present and our future generations. Guided by the circular economy principles, we designed battery technology to deliver on the promise that people around the world can power their lives better. It is critical that we don’t repeat the mistakes of the past by using our scarce resources in a way that is irrecoverable – there must be a way to be technologically advanced whilst also being kind to the environment around us.

Where do you see Aceleron in 10 years?

Aceleron is on a mission to positively impact the lives of at least 10million people around the world, providing easier access to energy for those that need it. To achieve this, we need to be a catalyst for change, making energy storage more affordable and sustainable, empowering communities in a way which considers the environment and creates sustainable business opportunities for all involved. Aceleron will be the foundation for positive and sustainable change as the world continues to rapidly electrify.

Do you have competitors in this space – if so, what makes Aceleron different?

Lithium batteries are becoming more and more used as our reliance on renewable energy sources increases. A vast majority of lithium batteries are made using permanent assembly technologies (e.g. spot welding) which means that they cannot be easily maintained or recycled. Aceleron is strictly using a compression approach to battery pack assembly which enables easy maintenance and recycling.

To learn more about how Aceleron is revolutionizing energy storage click here